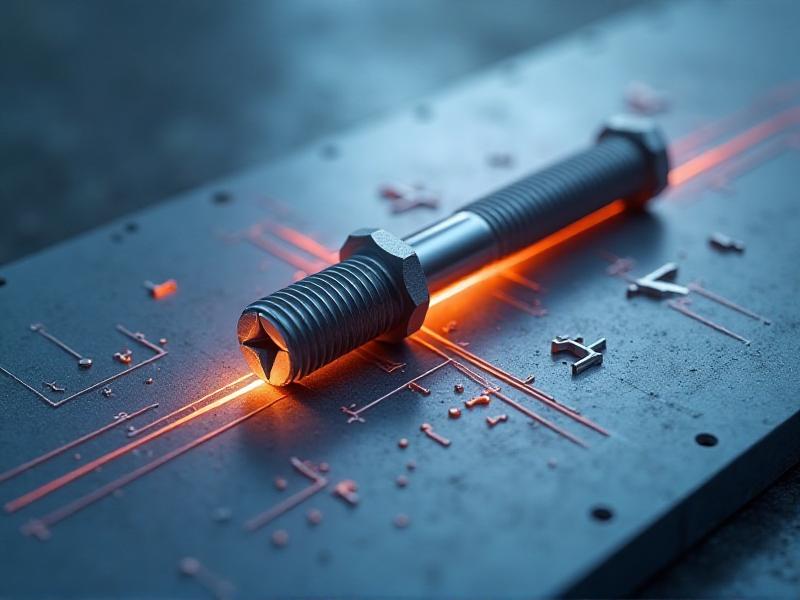

Removing Stubborn Bolts with Heat Cycles

Understanding the Challenge of Stubborn Bolts

Stubborn bolts are a common frustration for mechanics, DIY enthusiasts, and anyone working with machinery. These bolts, often corroded or seized due to years of exposure to moisture, dirt, and temperature fluctuations, can resist even the most determined efforts to remove them. Traditional methods like applying penetrating oil or using a wrench often fall short, leaving you with a stripped bolt or a broken tool. This is where heat cycles come into play—a technique that leverages the power of thermal expansion and contraction to break the bond between the bolt and the material it’s fastened to. By understanding the science behind this method, you can tackle even the most unyielding bolts with confidence.

The Science Behind Heat Cycles

Heat cycles work by exploiting the physical properties of metal. When metal is heated, it expands; when it cools, it contracts. This principle is key to loosening stubborn bolts. By applying heat to the bolt and the surrounding material, you create a difference in expansion rates. The bolt expands slightly, breaking the bond with the threads. As it cools, it contracts, creating tiny gaps that allow you to apply torque more effectively. The key is to use controlled heat—too much can damage the surrounding material, while too little won’t achieve the desired effect. Understanding the thermal conductivity of the materials involved is crucial for success.

Tools and Equipment You’ll Need

To effectively remove stubborn bolts with heat cycles, you’ll need the right tools. A propane or butane torch is the most common heat source, offering portability and ease of use. For more precise applications, an induction heater can provide targeted heat without affecting surrounding areas. Protective gear, such as heat-resistant gloves and safety goggles, is essential to prevent burns and eye injuries. Additionally, having a quality wrench or socket set ensures you can apply the necessary torque once the bolt is loosened. Penetrating oil can also be used in conjunction with heat cycles to further break down corrosion and lubricate the threads.

Step-by-Step Guide to Applying Heat Cycles

Removing a stubborn bolt with heat cycles involves a systematic approach. First, clean the area around the bolt to remove dirt and debris. Apply penetrating oil and let it sit for a few minutes to seep into the threads. Next, use your torch or induction heater to apply heat evenly to the bolt and the surrounding material. Aim for a temperature that causes the metal to expand but not warp. Once heated, allow the bolt to cool slightly before attempting to turn it with a wrench. If it doesn’t budge, repeat the process, gradually increasing the heat if necessary. Patience is key—rushing the process can lead to damage or injury.

Safety Precautions When Using Heat

Working with heat requires caution to avoid accidents. Always wear protective gear, including gloves, goggles, and flame-resistant clothing. Ensure your workspace is well-ventilated to prevent the buildup of harmful fumes. Keep a fire extinguisher nearby in case of emergencies, and avoid heating bolts near flammable materials. Be mindful of the temperature—overheating can weaken the metal or cause it to fracture. Additionally, allow the heated components to cool sufficiently before handling them to prevent burns. By following these safety measures, you can minimize risks and focus on the task at hand.

Common Mistakes to Avoid

Even experienced mechanics can make mistakes when using heat cycles to remove bolts. One common error is applying too much heat too quickly, which can damage the bolt or the surrounding material. Another is failing to let the bolt cool sufficiently before attempting to turn it, which can strip the threads or break the tool. Using the wrong type of wrench or socket can also lead to frustration. Additionally, neglecting to clean the area or apply penetrating oil beforehand can reduce the effectiveness of the heat cycles. By being aware of these pitfalls, you can approach the task more strategically and achieve better results.

When to Seek Professional Help

While heat cycles are an effective method for removing stubborn bolts, there are situations where professional assistance is warranted. If the bolt is in a critical or hard-to-reach location, such as an engine block or structural component, improper removal could cause significant damage. Similarly, if repeated attempts with heat cycles fail, it may indicate a deeper issue, such as thread damage or a seized fastener. In such cases, consulting a professional mechanic or technician can save time, money, and frustration. They have specialized tools and expertise to handle even the most challenging scenarios safely and efficiently.

Maintaining Bolts to Prevent Future Issues

Prevention is always better than cure, and this applies to bolts as well. Regular maintenance can help prevent them from becoming stubborn in the first place. Apply anti-seize compound to the threads before installation to reduce the risk of corrosion. Periodically inspect bolts for signs of rust or wear, and replace them if necessary. Keep fasteners clean and free of debris, and avoid over-tightening, which can stress the threads. By taking these proactive steps, you can extend the life of your bolts and minimize the need for heat cycles or other removal techniques.

Exploring Alternative Methods

While heat cycles are highly effective, they’re not the only option for removing stubborn bolts. Mechanical methods, such as impact wrenches or bolt extractors, can be useful in certain situations. Chemical solutions, like rust dissolvers or penetrating oils, can also help break down corrosion. For bolts that are completely seized, cutting or drilling may be necessary, though these methods should be used as a last resort. By understanding the strengths and limitations of each approach, you can choose the best method for your specific situation and increase your chances of success.