Diamond Stone Grit Progression Systems

Understanding Diamond Stone Grit Progression Systems

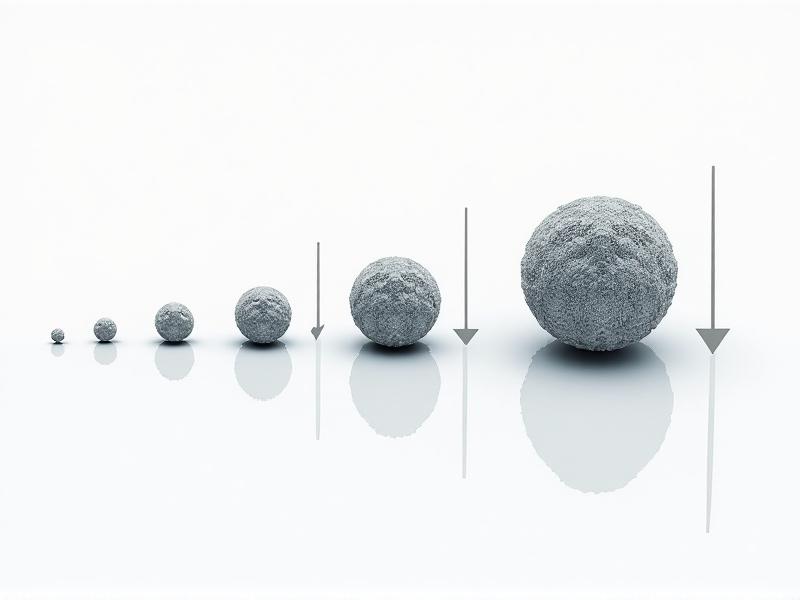

Diamond stone grit progression systems are essential tools for achieving precision and perfection in sharpening and polishing tasks. These systems utilize diamond particles embedded in a matrix to remove material from a surface, progressively refining it to the desired finish. The grit progression refers to the sequence of diamond stones used, starting from coarse grits to remove significant material and moving to finer grits for a polished finish. Understanding this progression is crucial for anyone looking to master sharpening techniques, whether for kitchen knives, woodworking tools, or precision instruments.

The Science Behind Diamond Stone Grit

Diamond stone grit is measured in microns, with lower numbers indicating coarser grits and higher numbers representing finer grits. The science behind this measurement lies in the size of the diamond particles and their ability to remove material. Coarse grits, typically ranging from 100 to 400 microns, are designed for rapid material removal and shaping. Medium grits, around 600 to 1200 microns, refine the surface and prepare it for polishing. Fine grits, exceeding 2000 microns, provide a mirror-like finish. The choice of grit depends on the material being worked on and the desired outcome, making it essential to understand the science behind grit selection.

Choosing the Right Grit Progression for Your Needs

Selecting the appropriate grit progression is a critical step in achieving optimal results. For heavy-duty tasks like repairing chipped blades or reshaping tools, starting with a coarse grit is necessary. For routine sharpening, a medium grit progression is often sufficient. When aiming for a polished edge, finishing with fine grits is essential. It's also important to consider the material being sharpened; harder materials like steel may require a different grit progression compared to softer materials like wood. By understanding your specific needs and the properties of the material, you can choose the right grit progression for your project.

Step-by-Step Guide to Using Diamond Stone Grit Progression

Using a diamond stone grit progression system effectively requires a methodical approach. Start by securing the material to be sharpened, ensuring it remains stable throughout the process. Begin with the coarsest grit, applying consistent pressure and maintaining a steady angle. Move to the next grit in the progression, repeating the process until you reach the finest grit. Each step should involve checking the edge for consistency and smoothness. It's crucial to clean the stones between grits to prevent contamination and ensure optimal performance. Following this step-by-step guide will help you achieve a sharp, polished edge with precision.

Maintaining Your Diamond Stone Grit Progression System

Proper maintenance of your diamond stone grit progression system is essential for longevity and performance. After each use, clean the stones with water and a soft brush to remove any debris or metal particles. Store them in a dry, protected area to prevent damage or contamination. Periodically check the stones for wear and tear, as worn-out stones can affect the sharpening process. For heavily used stones, consider using a flattening stone to restore their surface. By maintaining your diamond stone grit progression system, you ensure consistent results and extend the life of your tools.

Common Mistakes to Avoid with Diamond Stone Grit Progression

Even experienced users can make mistakes when using diamond stone grit progression systems. One common error is skipping grits, which can lead to an uneven edge and increased effort in the final stages. Applying too much pressure can also damage the stones and the material being sharpened. Neglecting to clean the stones between grits can result in contamination, affecting the sharpening process. Another mistake is using the wrong grit progression for the material, leading to suboptimal results. By being aware of these common mistakes, you can avoid them and achieve better outcomes with your diamond stone grit progression system.

Advanced Techniques for Diamond Stone Grit Progression

For those looking to take their sharpening skills to the next level, advanced techniques with diamond stone grit progression systems can provide even greater precision and control. Techniques like freehand sharpening, where the angle is maintained by feel rather than a guide, require practice but offer greater flexibility. Using a strop after the finest grit can further refine the edge, achieving a razor-sharp finish. For intricate tools or materials, custom grit progressions tailored to specific needs can yield exceptional results. By mastering these advanced techniques, you can elevate your sharpening and polishing capabilities to new heights.

The Future of Diamond Stone Grit Progression Systems

As technology advances, so too do diamond stone grit progression systems. Innovations in diamond particle bonding and matrix materials are leading to more durable and efficient stones. Smart sharpening systems with built-in angle guides and digital feedback are becoming more accessible, making precision sharpening easier for beginners. Environmental considerations are also driving the development of eco-friendly diamond stones. The future of these systems promises even greater precision, durability, and accessibility, ensuring that they remain indispensable tools for sharpening and polishing tasks.