Anvil Ring Test Interpretation Guide

Understanding the Anvil Ring Test: A Comprehensive Guide

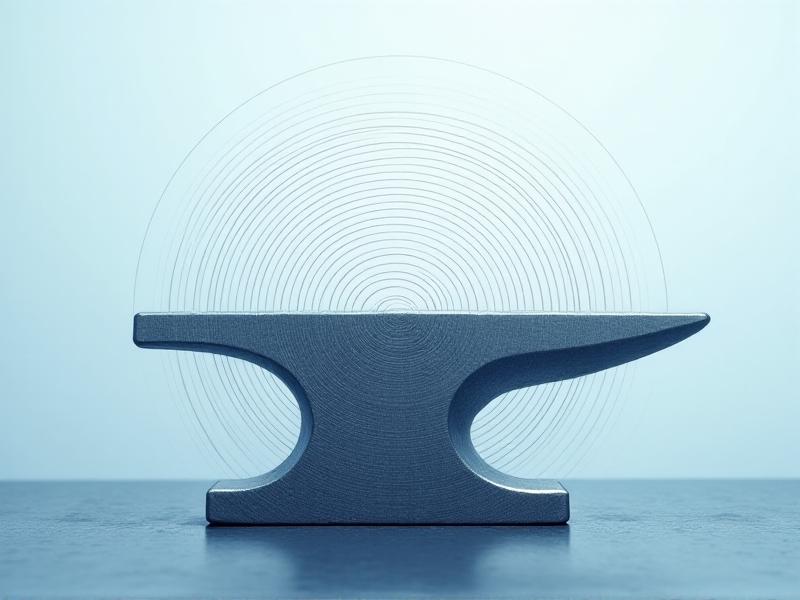

The Anvil Ring Test is a critical procedure used in metallurgy and blacksmithing to assess the quality and integrity of an anvil. This test involves striking the anvil with a hammer and listening to the resulting sound. The tone, duration, and clarity of the ring provide valuable insights into the anvil's condition, material composition, and potential flaws. Understanding how to interpret these sounds can help craftsmen and metallurgists make informed decisions about the anvil's usability and maintenance.

Historically, the Anvil Ring Test has been a trusted method for evaluating anvils, especially in traditional blacksmithing. The test is rooted in the principles of acoustics and material science, where the sound waves generated by the strike travel through the anvil and reflect its internal structure. A clear, high-pitched ring typically indicates a solid, well-made anvil, while a dull or muffled sound may suggest cracks, voids, or inferior materials.

The Science Behind the Anvil Ring Test

The Anvil Ring Test is deeply rooted in the physics of sound and material properties. When a hammer strikes the anvil, it generates vibrations that travel through the metal. These vibrations produce sound waves, which are influenced by the anvil's density, elasticity, and internal structure. A high-quality anvil, made of homogeneous and defect-free steel, will produce a clear, resonant ring with a sustained tone. This is because the sound waves travel uniformly through the material without significant energy loss.

Conversely, an anvil with internal flaws, such as cracks, air pockets, or uneven density, will produce a dull or inconsistent sound. These flaws disrupt the propagation of sound waves, causing them to scatter or dissipate prematurely. Additionally, the shape and size of the anvil can affect the sound. Larger anvils tend to produce lower-pitched tones, while smaller ones generate higher pitches. Understanding these scientific principles is essential for accurately interpreting the results of the Anvil Ring Test.

Step-by-Step Guide to Performing the Anvil Ring Test

Performing the Anvil Ring Test requires precision and attention to detail. Begin by selecting a suitable hammer—preferably one with a flat, smooth face to ensure a clean strike. Position the anvil on a stable surface, such as a wooden stand or a concrete floor, to minimize external vibrations. Strike the anvil firmly but not excessively, as too much force can damage the tool or produce misleading results.

As you strike the anvil, listen carefully to the sound it produces. A high-quality anvil will emit a clear, ringing tone that lasts for several seconds. Pay attention to the pitch, duration, and consistency of the sound. If the tone is dull, short, or uneven, it may indicate internal flaws or poor material quality. Repeat the test at different points on the anvil's face to ensure a comprehensive assessment. Document your observations for future reference and comparison.

Interpreting the Results: What the Sounds Mean

Interpreting the results of the Anvil Ring Test requires a trained ear and a solid understanding of the factors that influence the sound. A clear, resonant ring with a sustained tone is a positive sign, indicating a well-made anvil with minimal internal flaws. This type of sound suggests that the anvil is made of high-quality steel and is suitable for heavy-duty use.

On the other hand, a dull or muffled sound may indicate cracks, voids, or inferior materials. If the tone is inconsistent or varies across different points on the anvil, it could suggest uneven density or structural issues. Additionally, a short or abrupt sound may indicate that the anvil is too small or lacks the necessary mass for effective use. By carefully analyzing these sounds, you can determine whether the anvil is in good condition or requires repairs or replacement.

Common Issues Detected by the Anvil Ring Test

The Anvil Ring Test is an effective tool for identifying a range of issues that can affect an anvil's performance and longevity. One common issue is internal cracking, which can occur due to repeated stress, improper use, or manufacturing defects. Cracks disrupt the propagation of sound waves, resulting in a dull or inconsistent tone. Another issue is the presence of voids or air pockets within the metal, which can weaken the anvil and reduce its effectiveness.

Inferior materials or poor manufacturing processes can also be detected through the Anvil Ring Test. Anvils made from low-quality steel or those with uneven density may produce a muffled or short-lived sound. Additionally, wear and tear over time can affect the anvil's performance, leading to changes in the sound it produces. By identifying these issues early, you can take corrective measures to restore the anvil's functionality or replace it if necessary.

Tips for Maintaining Your Anvil's Quality

Proper maintenance is essential for preserving the quality and performance of your anvil. Regularly inspect the anvil for signs of wear, such as cracks, chips, or uneven surfaces. Clean the anvil after each use to remove debris and prevent rust. Applying a protective coating, such as oil or wax, can help maintain the metal's integrity and prevent corrosion.

Store the anvil in a dry, temperature-controlled environment to minimize exposure to moisture and extreme temperatures. Avoid using the anvil for tasks that exceed its intended capacity, as this can cause damage or accelerate wear. Periodically perform the Anvil Ring Test to monitor the anvil's condition and address any issues promptly. By following these maintenance tips, you can extend the lifespan of your anvil and ensure it remains a reliable tool for your craft.

Historical Significance of the Anvil Ring Test

The Anvil Ring Test has a rich history that dates back to the early days of blacksmithing and metalworking. In ancient times, blacksmiths relied on their senses and experience to evaluate the quality of their tools. The Anvil Ring Test emerged as a practical and reliable method for assessing anvils, allowing craftsmen to ensure their tools were fit for purpose. Over time, the test became a standard practice in the trade, passed down through generations of blacksmiths.

In addition to its practical applications, the Anvil Ring Test holds cultural significance in the world of metalworking. It represents the craftsmanship, skill, and dedication of blacksmiths who have shaped history through their work. Today, the test continues to be a valuable tool for modern craftsmen, bridging the gap between tradition and innovation. By understanding its historical context, we can appreciate the enduring importance of the Anvil Ring Test in the art and science of metalworking.

Modern Applications of the Anvil Ring Test

While the Anvil Ring Test has its roots in traditional blacksmithing, it remains relevant in modern applications. Today, the test is used not only by blacksmiths but also by metallurgists, engineers, and tool manufacturers to assess the quality of anvils and other metal tools. Advances in technology have enhanced the test's accuracy, with tools such as frequency analyzers and acoustic sensors providing detailed insights into the sound produced by the anvil.

In industrial settings, the Anvil Ring Test is used to evaluate the integrity of large metal components, such as those used in construction and manufacturing. The principles of the test have also been applied to other fields, including music and material science, where sound analysis is used to study the properties of various materials. By adapting the Anvil Ring Test to modern needs, we can continue to benefit from its simplicity and effectiveness in assessing metal quality.